Resistance Welding Machines

Pneumatic Spot Welding Machines :

RANGE : 15 –250 kVA

Details :

“KEJEARC” Pneumatic

Spot Welding Machines help join assemblies of two or more metal sheets economically, at high speeds. The contacting surfaces in the region of current concentration are heated by a short-time pulse of low voltage, high amperage current to form a fused nugget of the weld metal.

Features :

• Robust “C” STEEL FRAME assembly.

• STURDY RAM made of ground stainless steel permits high speed.

• Weld sequence control with squeeze, weld, hold & off.

• Microprocessor based WELD TIMER with SCR control.

• CONTROLLED MOVEMENT of upper electrode eliminating

hammer blow on job.

• HIGH SPEED operation i.e. up to to 140 SPOTS/MIN.

• NUGGET FORMATION assured.

• Good & CONSISTENT welds.

Application: The machines are suitable for a variety of applications including automobile bodies, furniture, control panels, weld mesh, electric appliances, fuel tanks, stainless steel tanks, etc.

Projection Welding Machines

RANGE : 50 –200 kVA

Details :

“KEJEARC” Projection Welding Machines are employed to carry out number of spot welds simultaneously in one welding cycle. It is used to joint stamped, forged or machined part to another part. Thus increase the productivity and carryout welding of special assemblies. Projection welding is becoming increasingly popular.

Features :

- STURDY “C” steel frame assembly

- Pressure and Height Adjustment make it suitable to weld DIFFERENT kind of jobs.

- WIDE CURRENT RANGE adjustment possible.

- Electronic circuit for PRECISE CONTROL of electrical inputs.

- Accurate 5-way timer with squeeze, weld, cool, post-weld, hold cycles.

- TAILOR MADE machines with fixtures.

- Choice of PLC.

Application:

- WELD-NUTS to SHEETS.

- FASTENER-BOLTS to SHEETS

- HANDLES to various SHEET ASSEMBLIES Including DRUMS & CONTAINERS.

- CROSS WIRE WELDING, for wire mesh.

- PINS, BRACKETS to DIFFERENT ASSEMBLIES.

- Welding of various AUTOMOBILE COMPONENTS.

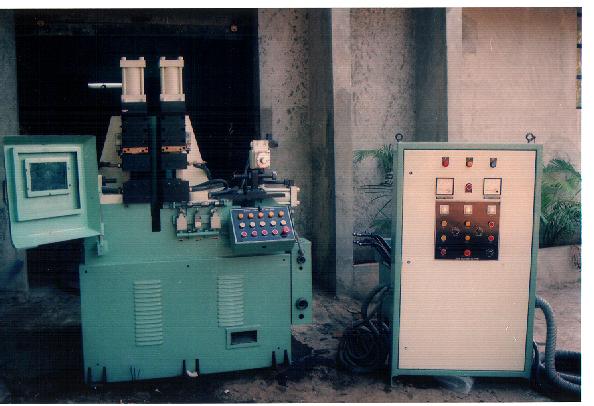

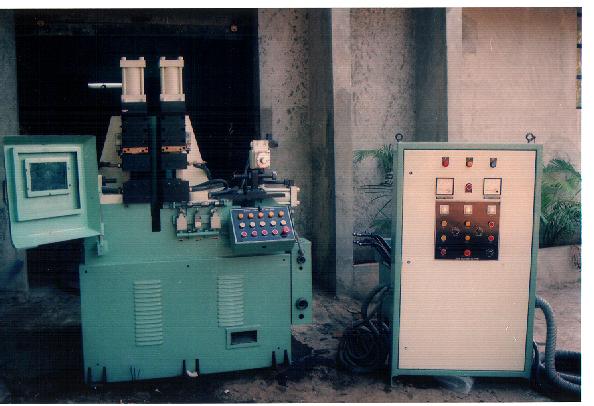

Seam Welding Machines

RANGE : UP TO 250kVA

Details :

Most industries are faced with the problem of achieving leak proof joints quickly economically and with minimum of distortion. The solution is “KEJEARC” Pneumatically operated Seam Welding Machine, for an uninterrupted weld run which results in a positive leak proof joint.

To obtain the true economy in production costs and utilize its advantages to the full, “KEJEARC” range of air operated Seam Welders are of modern design and incorporate a variety of alternative features ensuring that a suitable machine is available for every seam welding application within the range.

Features:

- LEAK PROOF JOINTS at much LOWER COSTS than conventional welding.

- HIGH QUALITY ROLLER BEARINGS carrying the roller shafts, guarantee longer-life of the roller bearings.

- STURDY DRIVE SHAFTS ensure non-slip drive.

- MINIMUM WEAR of the ELECTRODE WHEELS due to efficient cooling system.

- Fan Cooled transformer having core of high-grade silicon steel.

- THYRISTORISED HEAT CONTROL.

- HEAVY-DUTY HIGH SPEED OPERATION.

Application:

“KEJEARC” Seam welding machine is useful in the manufacturing of:

Cars, Buses, Trucks, Scooters, Auto-rickshaws, Drums, Containers, Barrels, Cans, Silencers, Water Tanks, fuel Tanks, Shells, Water Heaters, Electric Appliances, Textile Machines, Transformers, Motors, Television etc.

Flash Butt Welding Machines

RANGE : 15 – 250 kVA

Details :

Flash butt welding is a resistance welding process in which the jobs to be welded are securely clamped to electric current –carrying dies, heated by the electric current, and upset. “KEJEARC” Flash Butt Welding Machine has one stationery platen and other moving platen. Flashing raises the temperature of the abutting ends. At appropriate temperature upset force is applied, resulting in a good weld.

- Most Versatile machine for HIGH PRODUCTION.

- Welds of UNIFORM HIGH QUALITY are produced.

- EXTREMELY ECONOMICAL JOINTS produced.

- NO JOINT PREPARATION required.

- HYDRAULICALLY OPERATED clamping and flashing.

- FLASHING SPEED is fully ADJUSTABLE.

- THYRISTOR CONTROL.

- CHOICE OF PLC.

Application: Welding of Tubular parts, Bicycle & moped wheel RIMS, Constructional steel up to 32mm dia., Strip coils in continuous strips, Processing Lines, Chain links, Gear blanks, Window & Door sections is made easy with our seam welders.

Mini/Micro Spot Welding Machines

RANGE : 15 – 250 kVA

Details :

Flash butt welding is a resistance welding process in which the jobs to be welded are securely clamped to electric current –carrying dies, heated by the electric current, and upset. “KEJEARC” Flash Butt Welding Machine has one stationery platen and other moving platen. Flashing raises the temperature of the abutting ends. At appropriate temperature upset force is applied, resulting in a good weld.

- Most Versatile machine for HIGH PRODUCTION.

- Welds of UNIFORM HIGH QUALITY are produced.

- EXTREMELY ECONOMICAL JOINTS produced.

- NO JOINT PREPARATION required.

- HYDRAULICALLY OPERATED clamping and flashing.

- FLASHING SPEED is fully ADJUSTABLE.

- THYRISTOR CONTROL.

- CHOICE OF PLC.

Application: Welding of Tubular parts, Bicycle & moped wheel RIMS, Constructional steel up to 32mm dia., Strip coils in continuous strips, Processing Lines, Chain links, Gear blanks, Window & Door sections is made easy with our seam welders.